Portable appliance test (PAT) A portable appliance test does not need to be carried out by an electrician, but greater knowledge and experience is needed than for inspection alone, and the person performing the test must have the right equipment for the task. They should know how to use the test equipment and how to interpret the results. 2 Pocket guide to PAT testing Forward Following the publication of the Lofstedt report, back in November 2011, it was deemed necessary to look at the burden placed upon businesses due to a legislative over-compliance placed upon them – with a key issue being confusion over Portable Appliance Testing.

Companies aren’t obliged to maintain detailed records of the devices they have had PAT tested. Nevertheless, it is a very good idea that you do. By keeping records, you can see which of your electrical devices is due for a PAT Test, ensuring you meet obligations to keep staff and occupants safe. PAT Testing is also easier when there’s a definitive list of equipment to refer to, so it’s worth retaining records for next time around.

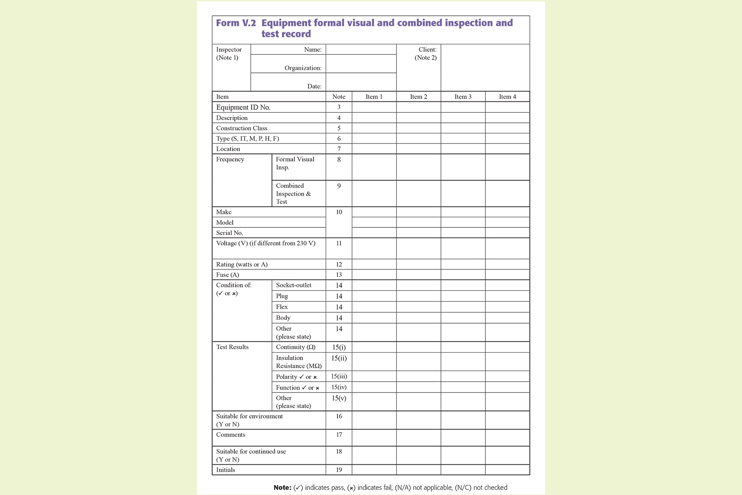

If your records have been lost, any competent PAT Testing company will provide you will their new records as proof that they have performed the necessary tests on your equipment. Such records will typically list each device that has been tested, its location, its class, and how it performs in each of the main parts of the PAT test: the visual inspection, the earth and insulation tests, and the functional check. Finally, the date that the device should next be tested will be given.

Legally, you don’t need to have a PAT Test certificate for every device that has passed. However, these certificates are issued routinely by PAT Testers, so it helps if you retain them. By having a PAT Testing certificate for a device, it proves that the device has been certified as safe to use, and therefore acts as a back up to prove that a company is in compliance with testing regulations. If someone takes you to court in future, you’ll be glad you have the paperwork to prove you’ve done everything you had to do to be safe.

Electricians carrying out PAT Tests may have carried out a formal training course with NICEIC or a similar provider. As part of their training, a PAT Tester will always learn how to issue PAT Testing certificates. Make sure you obtain yours once the tests are complete.

You can see some examples of PAT testing records here.

Download our comprehensive PAT guide today

Please note that PAT testing has changed due to the new 5th Edition guidance launched in Sept 2020. This guide is still relevant however we recommend viewing our 5th edition webinar to find out about the changes to the 4th Edition, which this guide is based on.

This 'How to PAT Test' guide will give you the knowledge to know how to PAT test to the latest IET 4th Edition code of practice.

Our portable appliance testers are the benchmark for the portable appliance testing (PAT) market and are regarded as number one by the industry. Our PAT testing equipment has always been designed with the needs of our customers in mind. Safety in the workplace is of paramount importance and our testers provide the quick and effective key to electrical equipment preventative maintenance programmes.

We have created the Seaward How to PAT Test guidance booklet because of our commitment to the PAT testing industry - Download this useful PAT testing guide today for a handy reference booklet with colour images and easy to digest chapters.

What's in Seaward's How to PAT Test Guide?

Legislation

This guide outlines the legal requirements and guidance relating to PAT testing and electrical safety including: Health and Safety at Work Act 1974 (HSW 1974), Management of Health and Safety at Work Regulations 1999, Electricity at Work Regulations 1989, Provision and Use of Work Equipment Regulations 1998, Housing Act 2004 (England and Wales), Housing (Scotland) Act 2006.

Who has responsibility?

This section explains who holds responsibility for PAT testing in the workplace, it explains who is classed as a duty holder and what is expected of them in relation to PAT testing. There is also some responsibility

Competence, Training and Experience

Identify what competence, training and experience is required by the user, the duty holder and the test operative carrying out the portable appliance testing of workplace equipment.

Types of Equipment

This section explains the differences between electrical equipment such as portable equipment and fixed appliances.

Pat Test Record Sheet Pdf Download

Classes of Equipment Construction

Learn how to determine whether an item is Class I or Class II construction so the correct test is performed.

The Inspection Process

This section details the process visual inspection.

Combined Inspection and Testing Procedure

Pat Testing Record Sheet Pdf

Understand what to do before and during tests including: in-service, Class I appliances, Class II appliances, fixed appliances, appliance cable sets, extension leads, multi-way adapters and RCD adapters. This section also details how to test hire equipment.

Electrical Tests

This section takes you through the following tests: earth continuity, insulation resistance, alternative or substitute leakage measurement, dielectric strength test (hipot test / flash test), preload check, load test and protective conductor/touch current measurement.

Pat Testing Record Sheet

Frequency of inspection and testing based on risk assessment

This section explains in detail, PAT testing frequency based on the IET code of practice for in-service inspection.

Record Keeping

This section gives recommendations of how to keep your records.